How to make dancing water fountain at home

How To Make a Dancing Water Fountain?

Do you want to create a beautiful water fountain that dances in sync with your favorite music? This extensive step-by-step guide will help you create one in your garden or home. Let’s dive right in.

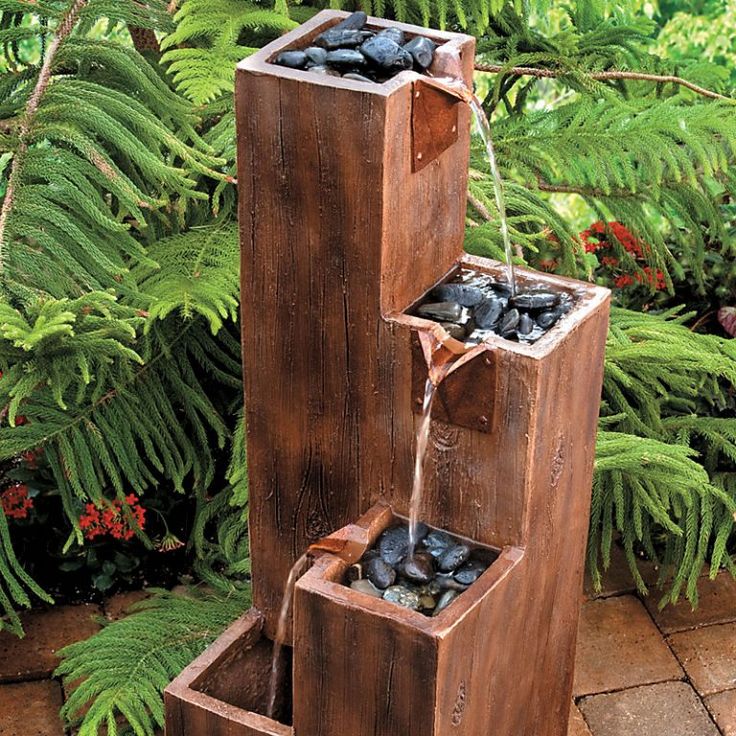

Water fountains can undoubtedly dramatically affect your yards, residential gardens, and other commercial projects. If you combine it with lighting and music, the aesthetics will make the visitors gaze for hours.

Dancing water fountains are gaining considerable popularity in big projects and cities with a high influx of tourists. The colorful lighting effect is combined with the gushes of water streams, creating a mesmerizing event. People from all over the world come to such places.

If you’re looking to boost your business by inviting more visitors, then adding a dancing water fountain to your project will do the job precisely. These lights, carefully placed underwater, added with the correct wattage, can easily become the focal point of any project.

But before heading on to place an order for water fountain lights, read this guide to learn how you can create and troubleshoot a stunning dancing water fountain. Moreover, we will discuss the benefits and tips on choosing the best LED water fountain lights.

Music Dancing FountainSteps Involved in Making a Dancing Water Fountain

If you’re inexperienced with electrical components, we advise you to help from our consultant to guide you through the process. Moreover, you can always hit up an expert electrician to help with the installation.

Setting up a regular lighted fountain indoors is more manageable, but if you’re installing a dancing fountain on a large scale, you need to ask for technical helping hands.

Here are the major steps involved in creating a dancing fountain.

1. Creating a Layout and Gathering ComponentsFirst, you need to define the size of the area of your water fountain. Then look for the design of your cybernetic system. These blueprints will help determine the final water choreography of your fountain project. Since dancing water fountain involves syncing of music with the water streams, the system requires thorough pre-analysis.

Then look for the design of your cybernetic system. These blueprints will help determine the final water choreography of your fountain project. Since dancing water fountain involves syncing of music with the water streams, the system requires thorough pre-analysis.

For this part, you would need to define two components, fountain nozzles, and water pumps.

· Fountain NozzlesFountain nozzles determine the flow of the water gushing out of the pool. For example, there are mainly five kinds of nozzles used in fountains.

- Crystalline Fountain Jets: These nozzles release a laminar flow of water

- Rotary Nozzles: For spirals and dynamic water flow, usually used in dancing and musical fountains

- Frothy Jets: Create a foamy flow of water; found chiefly in indoor fountains

- Spherical Shapes: Nozzles create a disk of water, ultimately giving the shape of a sphere

- Spray Nozzles: Such nozzles create a spraying effect

You can select multiple nozzles and arrange them in the Cybernetic formation to create a splendid design. Choose the number of fountain nozzles, types, their placement, the height, and finally, the angle of the water stream that will gush out of the nozzles.

Choose the number of fountain nozzles, types, their placement, the height, and finally, the angle of the water stream that will gush out of the nozzles.

Water pumps in fountains are used to pump the water using centrifugal force originating from a propeller. Pumps keep the water flowing throughout the cybernetic system. Now determine the following things to select the best type of pumps for your project.

- Submersible or dry pump: The names tell where which type of pump is used. It depends on your project. Use submersible pumps if you’re pumping water out of the pool. Dry pumps cannot be submerged in water. They are placed on the dry part of the fountain, such as concrete and bricks around it.

- Nozzles for pumps: Important for pulling off the music choreography of the project. Select nozzles compatible with the pumps.

- Pump power: How high do you want your water streams to go? It depends on the flow data that you have written in your pre-analysis document of the cybernetic system.

The pump power will be assigned to the nozzles that will pump the water out.

The pump power will be assigned to the nozzles that will pump the water out. - How to control the pump: Determine the type of control you will be opting for. Pumps can be controlled by frequency converter or direct starting process. Frequency converters are used to create the dynamic ascending and descending of the water streams during the dance. If your project doesn’t involve this movement, then direct starting pumps are used. Of course, the latter will be less expensive.

Solenoid valves are the control elements that can shut down, release, mix and move the fluids. They are responsible for the interactivity between different water jets and ultimately contribute to dynamism. It’s good practice to have a solenoid valve with every pump. However, depending on your structure, you can assign specific water pumps to have these valves.

· Water level controllersThese components control the height of the water stream during the event. Its system automatically handles the maximum and minimum height of the water stream.

Its system automatically handles the maximum and minimum height of the water stream.

This is technically a part of the previous step. Determine which lights would go best with your desired outcome.

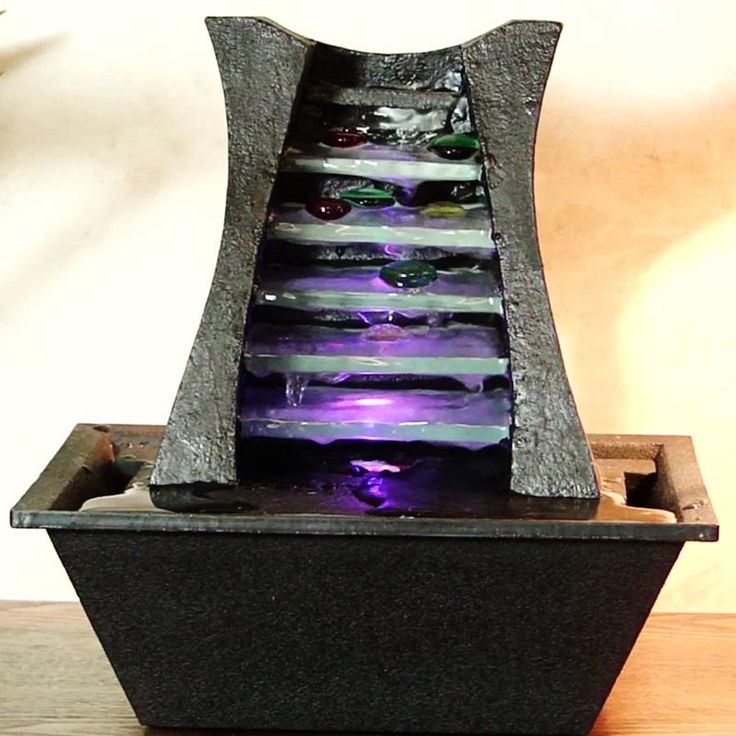

· LED Underwater Fountain LightsCompared to underwater incandescent bulbs, LED provides many advantages. LEDs are long-lasting, durable, robust, and most importantly, can be controlled by DMX controllers. A dancing fountain’s characteristic feature is the changing colors and intensities in sync with the music.

· Number of Lighting FixturesDetermine the total number of fixtures you require in the cybernetic structure. In this step, you also determine the location of these fixtures.

· DMX ControllerDetermine how you want the lights to behave during the event. You can either control individual lights or group them to perform in a union using a DMX controller. You can change the colors and synchronize them with the music. This analysis goes side by side with the previous two steps of determining the number of fixtures and their placement.

You can either control individual lights or group them to perform in a union using a DMX controller. You can change the colors and synchronize them with the music. This analysis goes side by side with the previous two steps of determining the number of fixtures and their placement.

For a complicated project involving music and color-changing lights synchronized to produce mesmerizing effects, you require an electrical panel to easily control all the functions. A custom-made panel will take care of all the controls and perform them automatically according to the feed information.

3. DMX Control Panel Set-UpThe electric panel (as mentioned before), also known as the control panel, must be designed by an electrician before the desired outcome. For this step, you need experts. Some manufacturers will take care of this according to your needs.

· Interactive FountainsDMX512 protocols are the most widely used systems to control lighting dynamics. It is used to cater to the complexity of the fountain design. You can easily program and control the dynamic using a laptop or tablet from a distance. Or you can automate the system entirely.

It is used to cater to the complexity of the fountain design. You can easily program and control the dynamic using a laptop or tablet from a distance. Or you can automate the system entirely.

For dancing fountains and other such projects, a DMX controller and specific software create the lighting sequences and music design. You can create your sequences and custom output designs as well. This software controls all your requirements in one place.

If your fountain is a non-musical project, you can sync lighting with the dance movement of water only without integrating music sequences. An expert programmer can perform this job accurately! Following is a general structure of a dancing water fountain.

interactive fountainsAll the electrical equipment should be installed when the pool is dry. It is essential to check and test the water pumps and lights’ working before filling the pool with water. Make sure all the equipment is fixed at its designated position on the base of the fountain pool.

Now that you’ve set up your dancing water fountain, you will require some tips on maintaining it and troubleshooting if you face any problems.

The most common issues that you’ll come across are:

- Too much splashing of water

- Noisy fountain

- Lowered water pressure with time

To avoid these problems, make sure you follow the following tips:

- Control the intake of the pump to prevent excessive water splash.

- Make sure that the pumps you have installed are fully submerged in the pool of water.

- The pumps should not be vibrating. Fix them inside your pool or place them firmly.

- Make sure all the connections are tight and secure.

- Sometimes windy weather conditions can disrupt the waters streams. To rectify such a situation, you can use ‘Anemometers’ to automatically stop the water streams when the wind reaches a certain high speed. These components also help in turning off the lighting and water pumps in great high winds.

Water fountains should be cleaned and maintained after a few weeks. This is important because water has many impurities which can accumulate in the water pumps, hoses, pipes, and other components. This adversely affects the overall performance and reduces the life of electrical components.

- Drain the fountain and clean thoroughly, making sure all the leaves and debris are gone.

- Use stain cleaners, scale removers, algaecides, and other water treatments to wash off the clogged pipes.

- In some areas, you might find green fungi and algae use fountain cleaners to get rid of them.

- Always use environmentally friendly products!

- Fill the pool with fresh water and add any good water treatment product.

In some areas where temperatures are extreme, you will have to protect the fountain and cover it during heavy snow and freezing weather.

- Remove all the water from the tank.

- Disconnect all the electrical components and store them somewhere safe.

- Make sure the basement of the fountain is covered with plastic or hay so that the snow doesn’t accumulate.

- Cover the fountain with fountain bags.

Now that you know what components are required to create a dancing fountain let us tell you what advantages you should be expecting from it.

This is a brief overview of how LED fountain lights are your best business-boosting strategy. We have gathered a few benefits fountain lights offer so you can take advantage of them. If you have a dead fountain on your lawn, bring it to life!

These 12/24 Volt Low Voltage LED Fountain Lights can be used in many types of fountains such as a dry fountain, garden ponds, outdoor stone fountains, dancing fountains, and music fountains.

Submersible Fountain Lights1. Relaxing Ambiance

Relaxing AmbianceThe relaxing environment is the first and foremost benefit that a dancing fountain will provide to you and your visitors. This element surely attracts the people and children to an unimaginable extent. In the hustle and bustle of today’s world, people look for such places to visit and calm their nerves.

If you’re looking to install water fountain lighting in your homes and gardens, don’t wait any longer! LED underwater lights can be single-colored or RGB/RGBW color-changing. You can leverage this point and create a healthy environment around your project. This will prove lucrative in many years to come.

The soft and soothing sound of water combined with comfortable and color is indeed therapy for stressed-out minds. Not to mention, the lights give a new magical feel to your fountains at night!

2. Enhanced ValueThe value of a property or project can be improved in many ways, such as highlighting important features and increasing security and safety. The look of any outdoor area can tremendously increase the value of that project. These water fountain lights can significantly uplift the outdoor look and appeal, skyrocketing the worth of a property. So, consider investing to gain a long-term benefit.

The look of any outdoor area can tremendously increase the value of that project. These water fountain lights can significantly uplift the outdoor look and appeal, skyrocketing the worth of a property. So, consider investing to gain a long-term benefit.

The life of underwater LEDs is not any shorter than the outdoor lights. LED water fountain lights are highly waterproof and watertight. These fixtures are designed with high-quality stainless steel in junction with other non-corrosive materials to enhance strength and durability. The manufacturers make sure all the components of underwater lights are tested to last long in the water body.

4. Energy EfficientLEDs, as we know, can provide up to ~80% saving on your electricity bills. It will be remiss not to add energy and cost-efficient options to your projects that can pay you back in multiplied amounts. LEDs do not require regular maintenance.

A well-lit fountain will improve the safety and security of the area. With safety comes value and more visitors. Children can play around the garden safely. The chances of any sort of accidents taking place will reduce.

How To Choose the Best Submersible LED Pond Fountain Spotlights?To see the dancing lighting fountain working splendidly, you need top-quality underwater LED lights. The synchronized choreography can be affected if any lights malfunction during the event and people can notice the disruption.

· Waterproof FixturesThe first thing is the waterproof quality of the fixtures. Find fixtures having IP68 or higher rating. They should be highly corrosion resistant and durable in the water. All the electrical components of the LEDs should be highly secure and watertight.

· Fixture MaterialStainless steel material is best suited for underwater fixtures as stainless steel is highly corrosion resistant and robust.

Lights underwater need to be bright so that the fountain pool in the night can be adequately lit. Some of the light disperses in the water, so you need high illuminance.

· Color OptionsYou can opt for single-colored LEDs or RGB/RGBW options to suit your fountain needs.

· Smart ControlThe best dancing architectural fountain uses the DMX controller to sync the movement with music and lighting. Traditional lights such as halogen and incandescent will prove to be non-efficient and costly in the long run. Choose the LED lights accordingly.

· Color of the LensesLEDs with colored lenses illuminate differently than clear lenses. The light coming through the colored lenses washes out and doesn’t give the best look. Keep this specification in mind.

Since the transmissive nature of the lenses can disperse light submerged underwater, you need bright colors and a high level of lumens.

· Number of LumensFor underwater lights, the preferable number of lumens is 2500-3500 lumens. The lights should not be excessively bright and uncomfortable for the eyes. Note that the water reflection can cause glaring at night if the light is not positioned well or not of optimum brightness.

underwater led fountain lightsFinal Thoughts

Creating a DMX-controlled dancing water fountain requires you to be extremely precise and accurate. Just any person can not do the custom programming of control panels and installation. Only expert programmers and technicians can perform the job well.

On the other hand, if you want to install fountain lights in your residential swimming pool, ponds, and indoor fountains, you can easily install our submersible LED pond fountain spotlights.

Buy Fountain Lights from RC Lighting

Choose the underwater color-changing fountain lights that the smart systems can perfectly control. We offer 5 years of warranty with each of our products! Any tiny flaw can cease the function, so we recommend choosing the products that come with warranties.

If you require consultancy feel free to contact RC lighting. Our LED underwater submersible lights are of the highest quality, and numerous certifications back this fact.

RC Lighting is a lighting manufacturer in China. We provide a one-stop solution for your indoor and outdoor lighting projects. Ask for a quote now!

Musical Water Fountain

Musical Water Fountain

Tao Jin, Tyler Dolen, Vandya Swaminathan

“Have the Bellagio in your OWN HOME!!”

Introduction:

Our final project is a musical water fountain loosely based on the fountain in front of the famed Bellagio hotel and casino. The basic idea of the project is to take an input from an iPod (or any sound source), sample the sound and break it down to different “sequencies” by Walsh Transform , then use the output to turn on various solenoid valves. We first used a two-stage low pass filter, and then performed Fast Walsh Transforms on the sound source to split the sounds into different frequency ranges. Each different range will correspond to a different valve which comprises a musical water fountain operating to the beats and rhythms of the song.

The basic idea of the project is to take an input from an iPod (or any sound source), sample the sound and break it down to different “sequencies” by Walsh Transform , then use the output to turn on various solenoid valves. We first used a two-stage low pass filter, and then performed Fast Walsh Transforms on the sound source to split the sounds into different frequency ranges. Each different range will correspond to a different valve which comprises a musical water fountain operating to the beats and rhythms of the song.

High Level Design:

Currently, we have split the sound source into eight frequency ranges. The reasons for eight fountain heads are: 1- aesthetically appealing and 2- there are 8 pins for a standard I/O port on the Atmel Microcontroller. Since the purpose of this final project is to create a water fountain, we needed a pressurized water source. Originally, we had thought about using fish pumps; but then realized they did not have enough pressure. The pressure coming from the sink is between 30 and 40 psi, and therefore we decided to attach our input source to the sink. See below (Fig. 1) for a block diagram of our high-level design:

The pressure coming from the sink is between 30 and 40 psi, and therefore we decided to attach our input source to the sink. See below (Fig. 1) for a block diagram of our high-level design:

Fig. 1 – High-level design of the “Musical Water Fountain”

The entire project can be placed on a wooden stand which rests over the sink, so the water will drip back into the sink and not splash all over the area around the project. The following diagram in Fig. 2 illustrates the design of our water fountain system.

Fig. 2 – Preliminary Design

Fig. 3 – Skinner Solenoid Valve

There are a few important functions we needed to implement in our project. At the start of our project, the sound source was sampled using the A/D converter on the Atmel microcontroller. From the A/D converter, the samples undergo a Walsh transform (implemented in software) to split the samples into various frequency ranges. From there the individual ranges activate the different output controls, which correspond to the opening and closing of the solenoid valves. The output controls can also activate the specific LEDs that correspond to the activated valve. In this manner, a user can both see the valves turn on and the corresponding LEDs light up. We also have pushbuttons to control the mode (single or multi) and to change the threshold.

From there the individual ranges activate the different output controls, which correspond to the opening and closing of the solenoid valves. The output controls can also activate the specific LEDs that correspond to the activated valve. In this manner, a user can both see the valves turn on and the corresponding LEDs light up. We also have pushbuttons to control the mode (single or multi) and to change the threshold.

Fig 4: Optoisolator circuit for safety concerns

There are a number of safety issues that we have to contend with in the implementation of our mini “Bellagio fountain”. Additionally, there are many user specifications we must also decide to minimize the safety risks. The obvious issue for our project is water damage. Most of our components cannot be mixed with water. Water will short out most of circuitry, and even cause minor electrical shock to the unlucky person standing near the project if this were to occur. We must ensure the water is separated from the electrical components with superior insulation. In order to do so, we decided to both electrically isolate the valves using the optoisolator circuit (see Fig. 4) and point the valves downward. The pressure needed to activate the valves also caused the water to shoot too high, and water was uncontrollably hitting everything around the sink when the valves were pointed upward.

We must ensure the water is separated from the electrical components with superior insulation. In order to do so, we decided to both electrically isolate the valves using the optoisolator circuit (see Fig. 4) and point the valves downward. The pressure needed to activate the valves also caused the water to shoot too high, and water was uncontrollably hitting everything around the sink when the valves were pointed upward.

Program/Hardware Design:

Software

One of the most difficult parts of our program was determining which transform we should use. Originally, we had decided to use the Fourier Transform, because we felt we understood it the best. However, the Fourier transform took too many cycles, and was not fast enough. We then had to determine whether to use the Fast Fourier transform, which splits the sound waves into different frequency ranges, or the Walsh transform. The Walsh transform is faster, and much easier to code; in fact Professor Land had already written a basic Walsh transform which we could modify for our purposes. Unfortunately, the Walsh transform does not directly break up the sound waves into frequency ranges. Instead, it breaks up the sound waves into sequency ranges, which has a linear relationship to frequency ranges. Rather than sine and cosine, the ranges are broken into cal and sal equations. The result is often thought of as "a poor-man's fast Fourier transform (FFT)" representing the conversion of a time-sampled signal into an equivalent frequency-sampled form. Every range has roughly 150 Hz frequency range. In the end, we chose the Walsh transform, due to its speed.

Unfortunately, the Walsh transform does not directly break up the sound waves into frequency ranges. Instead, it breaks up the sound waves into sequency ranges, which has a linear relationship to frequency ranges. Rather than sine and cosine, the ranges are broken into cal and sal equations. The result is often thought of as "a poor-man's fast Fourier transform (FFT)" representing the conversion of a time-sampled signal into an equivalent frequency-sampled form. Every range has roughly 150 Hz frequency range. In the end, we chose the Walsh transform, due to its speed.

Fig. 5: LED circuit

Another issue we had to deal with was how many valves should be activated at any given time. Originally, we had determined to only activate one valve at a time, due to concerns about water pressure. However, when we received Professor Land’s test code (which was designed for LEDs) multiple LEDs would turn on at any given time, and the result looked very good. We could not determine which mode was better, and so we implemented a button which would change the mode between single and multi. In single, only the sequency band with the most information would have its valve and LED activated. In multi, any sequency bands which have a content value above a certain threshold would light up.

We could not determine which mode was better, and so we implemented a button which would change the mode between single and multi. In single, only the sequency band with the most information would have its valve and LED activated. In multi, any sequency bands which have a content value above a certain threshold would light up.

Different songs respond better to different threshold values. If the song is a particularly muted song, a high threshold will allow no LEDs or very few to be activated. However, if the threshold is too low, all the LEDs will be activated. A default value of 40 was set for the threshold, but two buttons were implemented to allow the threshold value to be changed so all songs would be implemented correctly in our program.

For TCCR0 our prescalar is 64. This means that every 250 ticks in the program counter corresponds to one millisecond. Being that our OCR0 also equals 250, this means the program will call the interrupt compare handler every millisecond. While we check the ADC and update our Walsh transform values, we do not update the LEDs or the valve controls every millisecond. We only update these every 200 milliseconds, as the switching time for the valves would then be too much and the valves would not function properly.

While we check the ADC and update our Walsh transform values, we do not update the LEDs or the valve controls every millisecond. We only update these every 200 milliseconds, as the switching time for the valves would then be too much and the valves would not function properly.

Fig. 6: Electrical Components

Circuit

The sound source or music can be fed from any standard player (mp3, cd, walkman, pc) with the 3.5mm stereo phone jack. We used a simple 2-to-1 splitter so the music can be played through a speaker and inputted into the Analog to Digital Converter (ADC) port of the microcontroller at the same time. The sound source from a standard player (ex. mp3) can not be directly used for ADC because the output signal maximum amplitude is usually +/- 1.5 V. The input signal therefore needs to have a DC bias which eliminates negative voltages and still stay within the range of the ADC reference voltage of 5V. Even though the audible range of a human ear is 20Hz-20kHz, we decided to sample the music at 2kHz to allow for fast ADC conversion and simple breakdown of frequency ranges. At this sampling rate, we can detect tones at up to 1kHz which will cut off high frequency treble sounds but still be useful for decoding typical music. As a result, we low pass filtered the input signal through two stages for sharper cutoff at 1kHz, removed the DC component of the sound source, and then biased the signal at 2.5V. The following Fig. 7 shows the input circuit:

Even though the audible range of a human ear is 20Hz-20kHz, we decided to sample the music at 2kHz to allow for fast ADC conversion and simple breakdown of frequency ranges. At this sampling rate, we can detect tones at up to 1kHz which will cut off high frequency treble sounds but still be useful for decoding typical music. As a result, we low pass filtered the input signal through two stages for sharper cutoff at 1kHz, removed the DC component of the sound source, and then biased the signal at 2.5V. The following Fig. 7 shows the input circuit:

Fig. 7: Low Pass Filter and DC Bias circuit

We added additional functionality to our project by allowing the user to select the mode of operation for our valves and change the threshold values to produce the best pattern for the type of song playing. The three push buttons are “Mode”, “Threshold Up”, and “Threshold Down”. The default mode is set at single valve operation and the default threshold at 40. Pushing the Mode button will toggle between Single and Multi valve operation. The threshold value can range from 10-80 with a change of +/-10 depending on which button is pressed. All three push buttons have 20Kohm pull-up resistors and are soldered on to the protoboard.

Pushing the Mode button will toggle between Single and Multi valve operation. The threshold value can range from 10-80 with a change of +/-10 depending on which button is pressed. All three push buttons have 20Kohm pull-up resistors and are soldered on to the protoboard.

Fig 8: Atmel Microcontroller with Push Buttons

The output circuits consist of the LED display and the optoisolators for the On-Off control of the eight solenoid valves. Port B of the Atmel microcontroller is used as the output controls for both the LED and the valves. The LEDs and solenoid valves are arranged in Walsh Transform sequency order. We wired the LEDs and their respective valves from lowest sequency or frequency order on the left to the highest sequency range on the right. Since the valves are normally open, the LEDs and the valves need to turn “on” when the corresponding output pin is low. The use of inverters are needed to light the LEDs when the output is low. Optoisolators are used for each solenoid valve so they can be driven by 24V power supply and also isolate the MCU from potentially harmful inductive spikes. Fig. 9 is a circuit diagram of the output controls and LED displays.

Optoisolators are used for each solenoid valve so they can be driven by 24V power supply and also isolate the MCU from potentially harmful inductive spikes. Fig. 9 is a circuit diagram of the output controls and LED displays.

Fig. 9:Output Circuit (LED and Optoisolator)

Hardware

Fig. 10: Hardware Setup

Figure 10 shows a photo of our musical water fountain. For a water source, we use any standard kitchen/bathroom sink. A three stage adapter screws into the faucet connection and reduces it to 3/8’’ ID poly tubing. This tube is then sent into a port on the back of our container. Figure 10 is a diagram showing how water is distributed to the eight valves. After the first T splitter, the tubing is reduced to 3/16’’ ID. This size is based on the adapters and splitters we were able to sample free of cost. We also felt that since the input 3/8’’ tubing is being split eight ways, reducing the tube size would help maintain water pressure, which was an ongoing concern. The design is fairly straightforward – coming in with single tube, the water is divided using T splitters into 2, 4, and then 8 different connections. All T splitters and connections to the valves are quick connect fittings, which as the name states are much easier than using barbs and hose clamps. At first we were concerned, but the quick connect fittings are strong enough to handle our water pressure, and we had no leaks from these at any point during testing.

The design is fairly straightforward – coming in with single tube, the water is divided using T splitters into 2, 4, and then 8 different connections. All T splitters and connections to the valves are quick connect fittings, which as the name states are much easier than using barbs and hose clamps. At first we were concerned, but the quick connect fittings are strong enough to handle our water pressure, and we had no leaks from these at any point during testing.

The valves used in our project are 3-way, which was not our original design. We originally planned on having 2-way valves, and a separate, single outlet control for the water in case all valves are off. However for these 3-way valves when a voltage is applied, any water being pumped to the input is sent out the third port. Another set of quick connect adapters is screwed into these outlet ports and connected in similar fashion to the inputs, with a separate outlet tube for each set of four valves. This system adequately handles water and prevents leaks when water is on, but all valves are turned off.

Another decision we had to make was how to secure the valves to our plastic container, ensuring that only the output tip would be outside the container. Each valve came with an adapter screwed on the top output port (see Figure 10). We decided to cut a hole in the top of the container small enough that the tip of the valve would stick through the lid. Then screwing the adapter on from the outside locks the valve into place. Eight equally spaced holes were measured and marked, and the eight valves fit in the container perfectly. At first we were unsure how to cut the holes in the lid, since the plastic can shatter when cut. Based on a suggestion from Professor Land, we heated a nail and used it to burn the holes in the lid. After using a knife to clean up the edges, we had eight properly sized holes to secure the valves onto the lid. The benefit of this setup is that no additional adapters or tubing are needed in order to visibly shoot water from the container.

Fig. 11: Valve Setup

11: Valve Setup

One notable feature of our project is that it was originally planned as a fountain that would shoot water up in the air from the valves, and then have it fall back down into a collection container. As will be discussed below, we were constantly plagued by water pressure difficulties. The eventual solution to this problem was, among other things, to turn our “fountain” upside down and have the container be directly above the sink and shoot water down instead of upward (See Fig. 11). With the aid of gravity, there is enough pressure to prevent the valves from being plugged and failing to re-open. This shift in our design was caused entirely by the nature of the valves, and we are confident that with more ideally suited valves, our initial design of an upward fountain would have succeeded. Because our valves now shoot down instead of up, there is no need for a collection container. By positioning the container above the sink, there is very limited splashing. As it turns out this design is cleaner and safer than our initial design. In order to position the contain above the sink we constructed stand from 2x4s that sits on the counter level with the sink, and the container rests approximately 16 inches above the counter.

In order to position the contain above the sink we constructed stand from 2x4s that sits on the counter level with the sink, and the container rests approximately 16 inches above the counter.

Evolution of Our Design

The implementation of our design underwent numerous revisions over the course of the project. First off, the solenoid valves we were able to obtain cheaply were much heavier duty than what we had planned on. Initial testing with our most powerful fish tank pump (~ 250 gallons/hr) hooked up to just one valve showed that we did not even have enough water pressure to power a single valve. The minimum pressure to have the valves shoot water out was higher than we could generate, and purchasing more pumps would cause us to far exceed our budget. To solve this problem, Professor Land suggested that we use a kitchen faucet to provide water to our valves. The line pressure for indoor plumbing is around 30 psi, far greater than what we could generate with a fish tank pump. Testing with the faucet hooked directly to a single pump, we found even turning the faucet on a little water would shoot to the ceiling. We thought our pressure problems were over.

Testing with the faucet hooked directly to a single pump, we found even turning the faucet on a little water would shoot to the ceiling. We thought our pressure problems were over.

Fig 12: Original Hardware Design

However this solution created a new problem - the need for an outlet for the water being pumped into the system. Fish tank pumps have an automatic shutoff, so if all the valves are closed, the pump senses the feedback and shuts off. This prevents the pump from continuing to pumping water into the tubing. However the faucet does not have this feature. Once the faucet is turned on, water is being continuously pumped into the input port of the solenoid valves. However for much of the time (especially in single mode), water is not being allowed to pass out the top of the valves. Without an outlet port, the pressure would build up within our tubing and most likely lead to a burst connection. The first design we constructed is shown in Figure 12. Water enters the container and is split into two directions, one to each set of four valves. This was done because we felt that if a manifold of eight valves in series was created, there may be pressure difficulties farther down the line if, for example, the first few valves in the line were powered. Two sets of four valves in series should alleviate this problem to some extent. The final valve in each line is then connected to an outlet tube that returns the water to the sink. Since we had outlet tubes in the design, we decided to cap the third port of the valves to prevent water from flowing through when the valve is deactivated. The valves came with plastic caps, which we glued using a heavy duty waterproof adhesive. Unfortunately, testing this design we found that we still had problems with water pressure. The fountain would work to music for a little while (10-20 seconds), but then the pressure would fail to fully open the valves. Instead of shooting water in the air like a fountain, water would just dribble out of the top.

Water enters the container and is split into two directions, one to each set of four valves. This was done because we felt that if a manifold of eight valves in series was created, there may be pressure difficulties farther down the line if, for example, the first few valves in the line were powered. Two sets of four valves in series should alleviate this problem to some extent. The final valve in each line is then connected to an outlet tube that returns the water to the sink. Since we had outlet tubes in the design, we decided to cap the third port of the valves to prevent water from flowing through when the valve is deactivated. The valves came with plastic caps, which we glued using a heavy duty waterproof adhesive. Unfortunately, testing this design we found that we still had problems with water pressure. The fountain would work to music for a little while (10-20 seconds), but then the pressure would fail to fully open the valves. Instead of shooting water in the air like a fountain, water would just dribble out of the top. In addition, when we attempted to plug our outlet tubes to test whether this would increase the pressure enough to open the valves, the pressure burst the glued caps out of the third port. This made us decide to use the third port as an outlet for each valve, and the water distribution was redesigned to the final method we used (described above).

In addition, when we attempted to plug our outlet tubes to test whether this would increase the pressure enough to open the valves, the pressure burst the glued caps out of the third port. This made us decide to use the third port as an outlet for each valve, and the water distribution was redesigned to the final method we used (described above).

Results of the design

video clip (22 Mbytes)

Speed of Execution

Our program cannot switch the valves instantaneously; there is a certain switching time which needs to be taken for the valves. We only update the valves every 200 ms, but even then there is a bit of a delay between the LEDs changing (which is practically instantaneous) and the valves switching. It becomes a slightly more prominent delay when the LEDs are placed next to the valves, but the only way to counteract his delay is to delay the output of the music somehow. Currently we have it playing straight to a speaker while it is being sampled; this is why the musical output is slightly faster than the rest of our outputs.

Accuracy

To test the accuracy of our Fast Walsh Transform (FWT) program we used the test code written by Professor Land which finds the maximum component of each sequency and displays the corresponding LED on the STK500. Since the FWT algorithm we used in this project does not take into account of the phase components of the signal, it is quite noisy from sample to sample even with a constant frequency input. Using the function generator to produce constant frequency signals with a peak to peak voltage of around 2V, we measured the rough frequency ranges of each LED output:

LED |

Freq Range (Hz) |

0 |

0-170 |

1 |

170-310 |

2 |

310-420 |

3 |

420-560 |

4 |

560-680 |

5 |

680-820 |

6 |

820-930 |

7 |

930-1000 |

As expected, LED0-7 each lit on in sequential order as the input frequency is increased from 0-1kHz. While the range varies for each LED output, there is roughly 100-150Hz difference in frequency between each order. As the input signal frequency is increased beyond 1kHz, the LED begin to cycle back down from 7. This is also expected since our sampling rate is at 2kHz which gives a maximum detection of up to 1kHz frequency range. Any higher frequencies will violate the Nyquist rate and result in aliasing in the frequency domain. Therefore a high frequency treble sound in a music signal will light up a low order LED and turn on the corresponding valve. While it is inconsistent, it does not really affect the goal of our project since the purpose of the valves is to operate according to the beat of the song being played.

While the range varies for each LED output, there is roughly 100-150Hz difference in frequency between each order. As the input signal frequency is increased beyond 1kHz, the LED begin to cycle back down from 7. This is also expected since our sampling rate is at 2kHz which gives a maximum detection of up to 1kHz frequency range. Any higher frequencies will violate the Nyquist rate and result in aliasing in the frequency domain. Therefore a high frequency treble sound in a music signal will light up a low order LED and turn on the corresponding valve. While it is inconsistent, it does not really affect the goal of our project since the purpose of the valves is to operate according to the beat of the song being played.

Safety

Due to the nature of our project, combining electricity with spraying water, safety was an obvious concern and led to a number of our design decisions. We performed our initial testing of a fish tank pump and single valve in a bathtub, with all 3 group members present. One person held the valve to ensure water sprayed back into the tub, one controlled the power for the valve and pump, and the third held the wiring to the valve so it did not come in contact with any water on the floor. The person holding the valve also wore rubber gloves as an added precaution. Once we were sure the valves worked, the next stage of our project involved the coding, circuit design, and circuit construction. Since no water was involved, there were fewer safety concerns. The only safety measures needed were for soldering our boards, we used eye protection and caution with the hot soldering iron. When we came to final testing, spraying water became a safety concern again. We now had a 24 V power supply, two solder boards, a protoboard, and a significant amount of wiring. Testing in the ECE lounge kitchen, we had the electrical components on one counter and long wires running to the valve container by the sink. We used one giant salad bowl to cover the circuits and power supply, and another to direct the water being sprayed up by the valves.

One person held the valve to ensure water sprayed back into the tub, one controlled the power for the valve and pump, and the third held the wiring to the valve so it did not come in contact with any water on the floor. The person holding the valve also wore rubber gloves as an added precaution. Once we were sure the valves worked, the next stage of our project involved the coding, circuit design, and circuit construction. Since no water was involved, there were fewer safety concerns. The only safety measures needed were for soldering our boards, we used eye protection and caution with the hot soldering iron. When we came to final testing, spraying water became a safety concern again. We now had a 24 V power supply, two solder boards, a protoboard, and a significant amount of wiring. Testing in the ECE lounge kitchen, we had the electrical components on one counter and long wires running to the valve container by the sink. We used one giant salad bowl to cover the circuits and power supply, and another to direct the water being sprayed up by the valves. This worked surprisingly well at controlling the water, although the floor did get wet. Our final design is actually much safer than our testing stages. Once we made the decision to change our fountain to a water fountain and have water shoot downward, we eliminated the concern of water spraying and hitting the power supply and circuits. Also, since the minimum pressure to keep the valves functioning caused water to shoot around 4-5 feet in the air (compared to our initial hopes of only a foot), our design is definitely much safer facing downward.

This worked surprisingly well at controlling the water, although the floor did get wet. Our final design is actually much safer than our testing stages. Once we made the decision to change our fountain to a water fountain and have water shoot downward, we eliminated the concern of water spraying and hitting the power supply and circuits. Also, since the minimum pressure to keep the valves functioning caused water to shoot around 4-5 feet in the air (compared to our initial hopes of only a foot), our design is definitely much safer facing downward.

Usability

The final version of our project is not quite as usable by others as our initial design. Our initial design was a single self contained unit, with a fish pump in the collection container supplying the water that would shoot up and fall back into the container. Once filled, it could keep running and be moved anywhere (power supply cord permitting). Our final design must be attached to a faucet, and must have some form of collection container below it that is connected to a drain. The easiest solution is how we demo it, positioned right above the sink that supplies the water. However aside from this constraint, our project is quite usable by both us and others. Any iPod or CD player is connected to the audio input with a standard speaker connection. The threshold value to activate the valves can be increased or decreased with a simple button push, so the project can be used with different volume audio inputs. There is no skill involved in operating our project – turn on the faucet, power supply, and audio input device, then watch the water fountain.

The easiest solution is how we demo it, positioned right above the sink that supplies the water. However aside from this constraint, our project is quite usable by both us and others. Any iPod or CD player is connected to the audio input with a standard speaker connection. The threshold value to activate the valves can be increased or decreased with a simple button push, so the project can be used with different volume audio inputs. There is no skill involved in operating our project – turn on the faucet, power supply, and audio input device, then watch the water fountain.

Conclusion

Our project evolved numerous ways over the course of the planning, execution, construction, and testing phases. However, the main goals and concept of our musical fountain (or water fountain) stayed the same and we were able to successfully achieve the desired results. While our end result did not come any close to the famed Bellagio water fountains in Vegas, we did have great satisfaction in building a water fountain (or fall) that can play to the beats and rhythms of our music source. We realized early on that some aspects of our project were too ambitious and we made the right changes to continue progress and ultimately accomplish the main goals we set in the beginning. For example, the solenoid valves we need in this project turned out to be very difficult to get because of their cost and the lack of free samples from valve manufacturers. Fortunately we were able to secure a lot of overstocked, outdated valves on Ebay for an extremely bargain price. Overall, this project turned out to be much more challenging and time consuming than we originally planned. A large amount of time was spent in mechanical engineering and construction on top of the circuit design, testing, and programming.

We realized early on that some aspects of our project were too ambitious and we made the right changes to continue progress and ultimately accomplish the main goals we set in the beginning. For example, the solenoid valves we need in this project turned out to be very difficult to get because of their cost and the lack of free samples from valve manufacturers. Fortunately we were able to secure a lot of overstocked, outdated valves on Ebay for an extremely bargain price. Overall, this project turned out to be much more challenging and time consuming than we originally planned. A large amount of time was spent in mechanical engineering and construction on top of the circuit design, testing, and programming.

There can be many improvements to our final design since most of it was due to material, cost, and time constraints. The ideal case would be to use 2-way miniature on-off solenoid valves that can operate on low pressure. This way we can truly implement a musical water fountain that sprays up instead of down. The valves also need to have very fast response time to minimize the delay between closing and opening of the orifice. Further improvements can include increasing the sampling rate of our Walsh Transform and have more valves to expand the range of frequencies covered. We could also mount LEDs next to each valve to improve the visual effects of our project.

The valves also need to have very fast response time to minimize the delay between closing and opening of the orifice. Further improvements can include increasing the sampling rate of our Walsh Transform and have more valves to expand the range of frequencies covered. We could also mount LEDs next to each valve to improve the visual effects of our project.

Ethical Considerations:

Patent 5439170 has a concept similar to us, but there is not enough documentation on how they implement it to see if it will gate us – All other fountain patents are not similar enough to our concept to prevent us from obtaining a patent. Most fountains have a pre-programmed, pre-choreographed valve control, rather than use the music itself to determine which valves turn on. Were we to have a larger budget, and perhaps a specific company backing, we could get a patent for our project

IEEE Code of Ethics:

1. to accept responsibility in making decisions consistent with the safety, health and welfare of the public, and to disclose promptly factors that might endanger the public or the environment;

Given that our project involves both water and electricity, we took very careful concern on safety and health issues. We made sure to protect all electronics from water contact, and even reversed the flow of our valves so water would not hit various people and items. We make sure anyone working near or on our project realizes the risks associated with it, and is extremely careful when standing near our project during actual execution.

We made sure to protect all electronics from water contact, and even reversed the flow of our valves so water would not hit various people and items. We make sure anyone working near or on our project realizes the risks associated with it, and is extremely careful when standing near our project during actual execution.

3. to be honest and realistic in stating claims or estimates based on available data;

We have been very honest about the limitations of our project. We never lied about the physical reasons behind reversing the direction of the valves, and the delay between the water control, light control, and the actual music output.

4. to reject bribery in all its forms;

We accepted no bribes.

5. to improve the understanding of technology, its appropriate application, and potential consequences;

We specifically chose this project despite a lack of knowledge in plumbing and Walsh transforms. Using the internet and expert resources, we learned everything we needed to know, and sometimes even applied the knowledge in a different way to complete our project. We purposefully stepped out of our comfort zone in order to complete this project.

Using the internet and expert resources, we learned everything we needed to know, and sometimes even applied the knowledge in a different way to complete our project. We purposefully stepped out of our comfort zone in order to complete this project.

6. to maintain and improve our technical competence and to undertake technological tasks for others only if qualified by training or experience, or after full disclosure of pertinent limitations;

Due to the dangerous nature of our project, safety was always a concern. We made sure we bored holes in plastic near an open window to minimize smoke inhalation, and asked professionals or our mechanical engineering friends to cut wood so we did not loose any digits.

7. to seek, accept, and offer honest criticism of technical work, to acknowledge and correct errors, and to credit properly the contributions of others;

We used any help that was offered. Professor Land helped us with the code, and also offered suggestions for physical design. Alex Fee helped us cut wood.

Alex Fee helped us cut wood.

8. to treat fairly all persons regardless of such factors as race, religion, gender, disability, age, or national origin;

Our lab group is extremely multi racial.

Appendix A:

Budget

Part |

Cost |

Custom PC Board |

$5 |

Mega 32 Chip |

$8 |

3/8” tubing (4 ft) |

$0. |

3/8” – ¼” barb adapter |

$1.52 |

4 Hose Clamp |

$2.36 |

Solder Board |

$2.50 |

2 Broken Solder Boards |

Free |

30V Power Supply for Valve |

Free |

Wood & Nails |

Free |

Plastic Box |

Free |

Opto-isolators, Resistors, Capacitors, Wires, Headers |

Free |

Power Supply |

$5 |

Quick Connects for Valves |

Free |

T-Connects |

Free |

5/16” tubing |

Free |

Sink Adapter |

$2. |

½’’ tube connecter |

$7.72 |

½” tube |

$0.33 |

8 Skinner 3-way valves |

$6.66 |

TOTAL |

$42.28 |

Appendix B:

Work Breakdown

Researching Valves/Pumps – ALL

Calling Companies for Free Samples – ALL

Debugging Code – TJ/Van

LED Circuit – Van

Optoisolator Circuit – Tyler

Input Circuit – TJ/Tyler

Building MCU Board – ALL

Shopping for Supplies/Research – ALL

Building Stand – ALL

Building Case for Valves – ALL

Connecting Valves & Tubing - ALL

Appendix C:

References

Data Sheets:

http://instruct1. cit.cornell.edu/courses/ee476/labs/s2006/LMC7111.pdf

cit.cornell.edu/courses/ee476/labs/s2006/LMC7111.pdf

http://instruct1.cit.cornell.edu/courses/ee476/labs/BUZ71.pdf

Websites:

www.kpiwebsite.com – Kelly Pneumatics

www.parker.com/skinner/ - Skinner Valves

www.ebay.com – Ebay

www.lowes.com – Lowes Home Improvement

www.homedepot.com – Home Depot

www.ithacaagway.com – Agway

www.freepatentsonline.com

Books:

Harwit, Martin, 1931- Title: Hadamard transform optics / Martin Harwit, Neil J. A. Sloane. Published: New York : Academic Press, 1979.

Sundararajan, D. Title: The discrete fourier transform : theory, algorithms and applications / D. Sundararajan. Published: Singapore ; River Edge, NJ : World Scientific, c2001.

Appendix D:

Code

musicalfountain.c

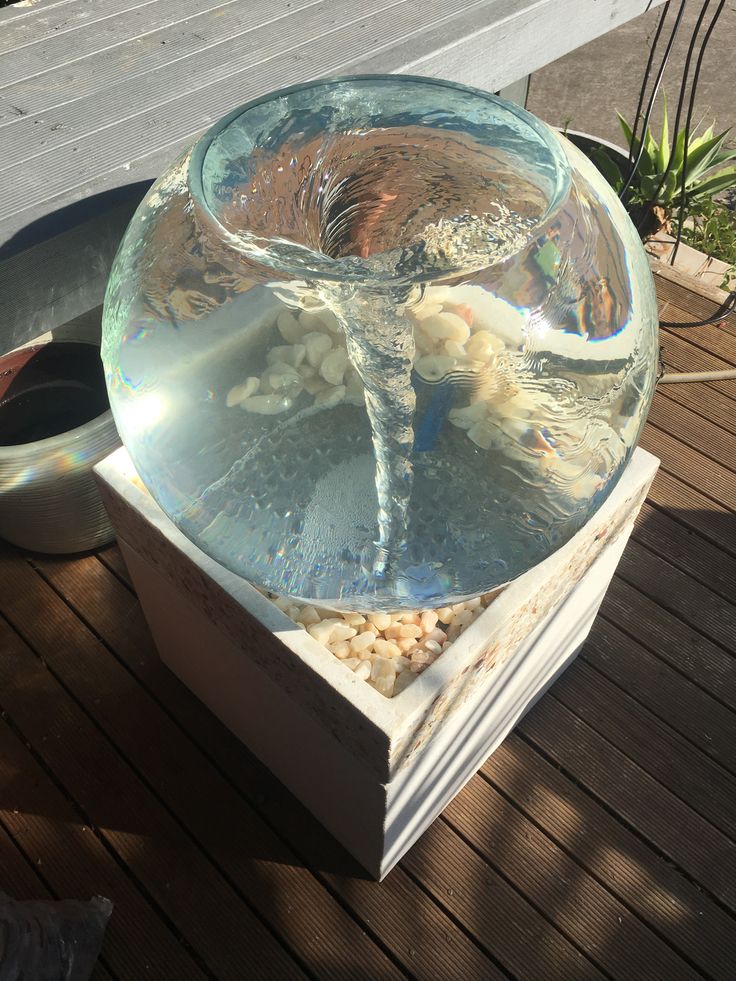

Do-it-yourself Heron's Fountain

In this article we will talk about what Heron's fountain is. This water device was known 2000 years ago. However, these days, few people think about how it works. Indeed, now there are many home fountains of various types on sale. But the peculiarity of this fountain is that it works without any engine, and you can make it yourself.

This water device was known 2000 years ago. However, these days, few people think about how it works. Indeed, now there are many home fountains of various types on sale. But the peculiarity of this fountain is that it works without any engine, and you can make it yourself.

No need to buy

DIY lovers will be happy to know that this device can be made quickly and easily. How to make Heron's fountain? First you need to prepare the materials and understand the principle of its work. It is not difficult to make a simple fountain of Heron with your own hands. Yes, and it consists of only two containers for water, tubes and a bowl. All these objects are interconnected and, thanks to the gravity existing on Earth, a jet of water is pushed out above the surface of the bowl. The fountain of Heron also operates in full accordance with the laws of hydropneumatics.

Parts

Each fountain container serves a specific purpose. Heron's fountain begins with a bowl. It is a bowl filled with water, from which a thin tube extends, directed into the lower container. It is through it that the water begins its movement. This container is empty. It accumulates water, which, rising up, creates pressure of air rising through a thin tube, and enters the upper container filled with water. From here, the air pushes the water, which moves through the tube into the bowl of water and creates a jet that is visible above the surface of the liquid. Heron's fountain can work for a very long time, but the containers have to be swapped. Because the lower one is gradually filled with water, and the upper one with air, which means that the necessary pressure ceases to be created.

It is a bowl filled with water, from which a thin tube extends, directed into the lower container. It is through it that the water begins its movement. This container is empty. It accumulates water, which, rising up, creates pressure of air rising through a thin tube, and enters the upper container filled with water. From here, the air pushes the water, which moves through the tube into the bowl of water and creates a jet that is visible above the surface of the liquid. Heron's fountain can work for a very long time, but the containers have to be swapped. Because the lower one is gradually filled with water, and the upper one with air, which means that the necessary pressure ceases to be created.

What is the secret

You might be surprised to read about how you can make a fountain with your own hands. After all, this model uses plastic, and 200 years ago it had not yet been invented. Everything is simple. The Greek inventor used glass containers. First, he conducted an experiment. He poured water into a glass bottle, then plugged it with a cork in which he made a hole. In this hole he inserted a tube that reached the bottom of the bottle. Having placed this structure in the sun, Heron began to observe it. The sun began to heat the bottle, and the water rushed up the tube. Moreover, the stronger the sun warmed, the more water flowed out. Then Heron took a magnifying glass and pointed it at the bottle to enhance the action of the sun's rays. Heated water burst out of the bottle in a high jet. This gave Heron the idea that water can move in a circle, rising from the bottle and returning to it. Then he began to think about how to make the water return to the container on its own.

He poured water into a glass bottle, then plugged it with a cork in which he made a hole. In this hole he inserted a tube that reached the bottom of the bottle. Having placed this structure in the sun, Heron began to observe it. The sun began to heat the bottle, and the water rushed up the tube. Moreover, the stronger the sun warmed, the more water flowed out. Then Heron took a magnifying glass and pointed it at the bottle to enhance the action of the sun's rays. Heated water burst out of the bottle in a high jet. This gave Heron the idea that water can move in a circle, rising from the bottle and returning to it. Then he began to think about how to make the water return to the container on its own.

What's next

The inventor came up with the idea of placing two more inside one vessel. The third vessel was empty, and the second was filled with water. Water enters the third vessel, creating air pressure, from which it rises up the tube located in the middle of the third vessel. From the second vessel, water begins to move into the third, expanding when heated by the sun's rays. As a result, viewers see the beating jet of the fountain above the surface of the bowl. Heron placed his first fountain in the temple. At that time, it was like a miracle, because no one could explain how this fountain works, because there were no mechanical devices or pipes to be seen through which water could be pumped.

From the second vessel, water begins to move into the third, expanding when heated by the sun's rays. As a result, viewers see the beating jet of the fountain above the surface of the bowl. Heron placed his first fountain in the temple. At that time, it was like a miracle, because no one could explain how this fountain works, because there were no mechanical devices or pipes to be seen through which water could be pumped.

Today

Heron's invention is still interesting to our contemporaries. It especially surprises children who are not yet familiar with the laws of physics. Modern inventors are gradually improving Heron's project. They add something new to it, improve its properties and, of course, come up with something of their own. For example, you can increase the height of the jet if you connect several containers together, then the pressure is summed up and pushes the water jet over a long distance. They also come up with various ways to recharge the fountain. It would be nice to make sure that a person does not have to take part in this process.

Nowadays, even a schoolboy can make a Heron Fountain with his own hands. How to make it - you read in our article. You can decorate this invention and install it in your country house or apartment, surprising your guests.

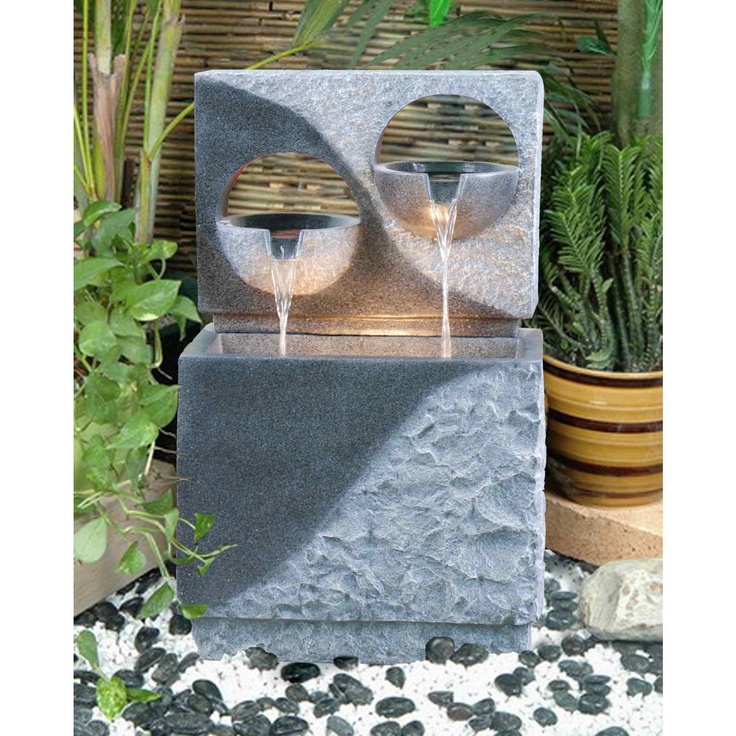

Do-it-yourself fountain - 100 photos and video instructions on how to make a real fountain

DIY fountain - how to make a decorative indoor or garden fountain at home (100 photos and videos) cold comes out. But this is not always possible, especially if you spend sultry summer days not in a noisy city, but in a village in the country.

Then you should think carefully, look at photos of home fountains and get down to business. If you are tormented by the question: how to make a fountain with your own hands , , then you can use large or small stones, even wheels or other products.

Thus, the fountain is an excellent decoration for a garden. It will complement the design, decorate the environment and make the place more comfortable. It will be especially pleasant to sit next to such a fountain on hot days and evenings. Add more decorations to it and let it please you and your family!

It will be especially pleasant to sit next to such a fountain on hot days and evenings. Add more decorations to it and let it please you and your family!

Review content:

Where should you start to make a mini fountain with your own hands?

First, you should carefully familiarize yourself with the types of fountains in the country and choose the option that seems most preferable to you. It is seriously worth approaching the choice of form, the materials from which the future fountain will be made.

It is customary to decorate a home fountain with various stones. They do this so that the fountain looks as natural as possible and looks like a natural waterfall.

Where should the fountain be placed?

To make a fountain in the country house , , you need to choose a suitable place, decide on a container, install a pump and complete the finished fountain with decorative elements.

Choosing the right location is a very important step in creating a home decorative fountain. If the place is chosen correctly, then this will positively affect the overall design and make the garden visually more attractive.

If the place is chosen correctly, then this will positively affect the overall design and make the garden visually more attractive.

The fountain is part of the overall design, so the chosen place should be both comfortable, functional and, of course, harmonious.

It is best to place the fountain next to the gazebo or the place where you spend most of your time. The fountain will humidify the air and will have an impact on the plants that are located next to it.

What criteria should be met when choosing a location for a fountain?

Access to electrical power so pump and other equipment can be easily turned on and off. The slope of the earth must also be taken into account. It is best to place the fountain in the lowlands.

Do not place in too sunny or close to trees. Do not place the fountain too close to the house, moisture will harm the walls. The best place is a well-visible place from all sides.

Fountain container

The container can be made independently or bought in a store.

The specialty shop has special bowls in different shapes. If you plan to lay a large fountain, then you will first need to dig a hole in the ground and make a foundation at its bottom.

Sand is placed on the bottom, and the side walls are reinforced with bricks. Then the surface is covered with a film. It should be such that it does not let water through.

What should be the material for the fountain?

Fountain material must be very durable. Strength is one of the main requirements for a material. But also the material must be sufficiently protected from temperature extremes. It is also desirable that the container and other elements of the fountain do not suffer from the action of water.

Plastic bowls are usually used as containers. And the walls are reinforced with bricks or ordinary stones. You can plant flowers next to the fountain.

You can plant flowers next to the fountain.

Decorative fountains: installation of a pump

A pumping system must be installed in order for the fountain to work. The pump is the main part of the installation, without which it will not work.

In order for it to serve properly, you need to choose a good option. The pump will drive water in a circle from the tank. The pumping system can be made of plastic pipes, they last a long time. Circulation pumps are usually selected for fountains. And the installation itself is supplemented with a receiver.

If you have already prepared a container, then simply put the purchased pump on the bottom and surround it with ordinary medium-sized stones.

After that, pour water into a container with a pump and stones. Pour enough water so that the pump is completely submerged in water. The water pressure will also depend on the power of the pump.

Fountain decorations

The fountain can be decorated with special nozzles that will make the water ejection interesting and even unusual. You can also add lighting or, for example, music.

You can also add lighting or, for example, music.

- The fountain is usually decorated with artificial flowers. It can be lilies, water lilies, water plants.

- Buy a variety of aquatic animals. Swans look especially good and harmonious, it is desirable that there are several of them.

- You can also add stones of different colors. For example, whites. If you buy swans, then white stones will look like laid eggs.

- Various vases are placed in the fountain container as decorative elements. Vases may be slightly cracked or even broken. The main thing before decorating the fountain is to pre-coat them with varnish.

- The fountain can be surrounded not only by stones, but also by a small decorative fence. Plant small flowers next to the fountain, the main thing is that they do not suffer from excess water.

- If you have children at home, then do not make the fountain too deep, let it be smaller.

Don't forget that decorative elements that you put in water will quickly become moldy.

92

92 27

27